Advancements in Automated Polishing, Buffing and Deburring

By Glen Carlson, Chairman

Acme Manufacturing Co.

Auburn Hills, MI

As we enter the new millennium, it might be constructive to critique the many changes we are experiencing in the way we must do business to survive, grow and prosper in an ever changing and expanding global market. Market pressures have never been more demanding, whether we are in the automotive or non-automotive sectors of the world economy.

In the U.S. market, there are tremendous changes occurring in our manufacturing facilities today to keep competitive and still maintain ever-increasing product quality standards. We are forced to find and implement better methods and procedures to meet ongoing global market demands. Many companies are developing the "Kaizen" approach to Continuous Improvement Programs, (TQM) Total Quality Management, ISO 9000, etc.

In the field of grinding, polishing, buffing and deburring, both large and small manufacturing plants must continue to upgrade their finishing operations and facilities. Manual finishing methods are becoming less desirable and highly ineffective as we plan to meet future manufacturing goals and projections. The available labor force today typically is not interested in working in "dirty" polishing departments, as there are many other much more appealing job opportunities. Also, current environmental rules and regulations help to discourage and limit hand grinding and deburring approaches in most U.S. plants. There is a definite trend to minimize hand-finishing operations, as well as to replace many of the older and long established polishing and buffing machines. Another option is to send this type of work off shore to the Far East, India, Latin America or Mexico; however this is not a good long-term solution. Problems with extended deliveries, excessive inventory of parts, additional shipping costs, quality issues and overall control negatively affects U.S. companies trying to find alternative sources to meet high-quality part supplies at controlled costs.

In defining mechanical finishing of specific part types related to various industries, basic categories can be classified under "decorative" and "functional."

Decorative Parts

Most metalworking plants

are faced with market pressures to upgrade their products in appearance

and performance, as well as improve their manufacturing cost base to better

meet domestic and worldwide competition. Especially on decorative consumer

products that are coated or plated, significant manufacturing costs are

directly related to polishing and buffing operations. Preparation by mechanical

surface finishing is important for decorative lock and plumbing hardware,

hand tools, cookware and appliances, lamps and lighting fixtures, golf

clubs, motorcycles, handguns and rifles, aluminum extruded building products,

automotive bumpers and cast aluminum wheels.

Functional Parts

On functional internal part components that affect product efficiency

and performance, deburring and super finishing are becoming important

secondary operations. With extended part warranties, such as in the automotive

field, quality control to ensure the integrity of the part components

becomes a key cost factor. Specifications for surface finish and geometry

of bearing and load surfaces for transmission shafts, gears, yokes, drums,

axles, camshafts, crankshafts, connecting rods, pistons and engine blocks

are being continually upgraded. Other non-automotive applications requiring

better controlled surface finish and tolerances are found on truck and

earth moving vehicles, medical prostheses or implants, pump screws and

valves, air compressor and air conditioner components, motor rotor components

aircraft engine compressor discs and blades, aircraft frame components,

and hydraulic telescopic cylinders.

The examples listed above represent only a portion of the total mechanical surface finishing applications that are influenced by current market factors. These market factors are causing many changes in the way we control and operate our plants.

Market Factors

The following are market

factors that affect decision making regarding mechanical surface finishing

operations and equipment.

- There is a need

for greater machine flexibility in finishing a wider range of products

on a common system with greater emphasis on rapid machine changeover,

simplified tooling and combined finishing operations within the same

system.

- The quality level

required continues to rise worldwide. Both cosmetic and functional finishing

specifications are better defined and controlled by continuing market

pressures. Part geometry, uniformity and consistency relative to surface

finish as well as visual specifications are essential as a result of

continuous quality improvement programs established in the automotive

and non-automotive industries. Kaizen, TQM, ISO 9000 and QS 9000, represent

current examples of how we must conduct our businesses today and in

the future to maintain our companies as qualified and acceptable suppliers

to our customers.

- Competitiveness in the marketplace is an ongoing factor.

Finishing costs have traditionally been significant, especially on decorative

consumer items. Not only have the labor costs been substantial, but

also the cost of buffs, compounds, abrasive belts, wheels and brushes

have been key contributors to the overall cost of the end product. There

has been a definite trend to develop more cost-effective ways to finish

products. Product development in the areas of buffs, compounds, abrasive

belts and wheels, nylon belts, brushes and wheels and micro-polishing

rolls has been a challenge to abrasive-media manufacturers. There are

many new products and options available today to help maintain higher

quality surface finishing standards at controlled costs.

a. A recent example in the field of coated abrasive belts, is the development of "structured abrasives." Coated abrasive belts use a technology known as "microreplication," which has given the ability to obtain precisely shaped composite grains bonded to a belt backing. More uniform fine belt finishes can be achieved to reduce sequential belt steps, extend belt life and ultimately improve final surface quality finishes at reduced operating costs.

- Stricter enforcement

of laws regarding operator safety, plant working conditions and hazardous

waste disposal has created a tremendous burden on our manufacturing

plants, to the point where many of the job shops and smaller plants

can no longer financially assume the costs incurred in meeting these

requirements. OSHA and other environmental regulations continue to be

enforced by local, state and federal agencies to help improve plant

safety and overall working conditions. Custom designed machine enclosures

are becoming much more common on finishing systems in order to protect

the operator in terms of reduced noise levels, dust and dirt air contamination,

and overall machine safety and exposure to potential plant hazards.

- High hidden costs

related to carrying in-process inventories, based on traditional batch-type

manufacturing operations, have forced most manufacturers to investigate

better methods of handling and scheduling production parts throughout

the plant. "Just-in-time" (JIT) manufacturing and "single-part flow

through" are two examples of improved inventory control being used throughout

many manufacturing plants. Specialized work cells combine a number of

machining and secondary finishing operations, using common operators

to perform multiple tasks within a given work cell. In these cases,

common part families can be conveniently routed within each line.

- Labor shortages

of qualified and trained personnel continue to affect most U. S. manufacturers.

Local, state and federal training programs are being expanded, but this

does not solve the complete problem. There must be other ways to offset

the lack of qualified labor pools. Programmable and flexible finishing

systems can also help to offset reduced labor conditions.

Robotic and Programmable Controlled Finishing Systems

As an answer to many market conditions and pressures outlined

above, electronic and computer hardware and software technology have been

developed for grinding, polishing, buffing, deburring and satin finishing.

Examples of current applications illustrate a variety of computerized

and programmable electronic systems that have been integrated into basic

mechanical finishing equipment and processes.

These systems address many of the critical market factors challenging modern manufacturing environments.

- Machine flexibility and rapid changeover;

- Improved part quality and consistency of finish;

- Reduced finishing costs and better utilization of abrasive media;

- Operator safety and environmental regulations;

- Improved parts handling and scheduling procedures to minimize inventory and in-process manufacturing costs; and

- The growing shortage of trained and qualified or willing labor.

The machine tool industry has been making excellent progress in addressing the market conditions and pressures outlined above. New programmable computer technology using Robotic, PLC, CNC and PC-based devices applied to mechanical finishing systems for grinding, polishing, buffing, deburring and satin finishing can be integrated into many robotic and programmable controlled finishing systems.

The following robotic and programmable controlled finishing systems illustrate and describe a variety of finishing applications for automotive and truck aluminum wheels, telescopic hydraulic cylinders, lock and plumbing hardware, aluminum building extrusions and a complete family of stainless steel ball valves. These typical applications cover a series of diverse mechanical finishing requirements necessary to establish typical bench marks into the new millennium.

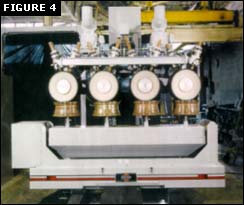

Case 1: Aluminum Cast and Forged Wheels

The automotive and truck industry has created a growing demand

for bright aluminum cast and forged decorative wheels. Figure

1 shows a variety of wheel designs, which are presently automatically

polished and buffed to a uniform mirror finish. For high production requirements,

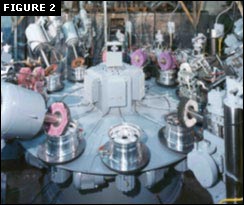

Figure

2 illustrates an eleven head rotary system provides the operator with

maximum buffing control in "cut" and "color" buffing automotive cast wheels.

In this case, the wheels are fixtured vertically to easily satisfy the

parts handling of the smaller automotive wheels. With eleven workstations,

electronic and programmable controls assist the operator to better monitor

and control the machine for rapid set-up and production operations.

|

|

In Figure 3, specially designed Acme O.D. and I.D. individual buffing heads perform a series of "cut" and "color" buffing operations on the inside surfaces of 22- and 24-inch diameter truck wheels on a large index table with wheels fixtured horizontally having specialized tooling for easier part handling.

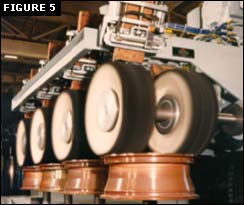

An alternative wheel buffing system for lower volume requirements provides a five-axis, four workstation machine as shown in Figures 4 and 5. A (CNC) computer numerical controlled buffing machine provides maximum flexibility for rapid machine changeover. Minimum tooling allows the four-station system to be more cost-effective for a variety of automotive wheel buffing requirements. The basic four-head arrangement can be set up for "cut" or "color" tangent wheel buffing or wide wheel "mush" buffing to meet lower production requirements. Various wheel designs are preprogrammed on the five-axis system, allowing machine changeover in a matter of minutes.

|

Case 2: Four-Head Abrasive-Belt Centerless Tube Grinding

System

A Four-Head Fully Programmable Centerless Abrasive Belt Grinding

and Polishing System provides high stock removal on telescopic hydraulic

cylinder tubes on a "single-pass-through" operation. A 15-axis programmable

controlled system is shown in Figure 6.

Approximately 0.60 inch stock removal can be ground to a controlled finish

and precise tolerance standards on thin-walled D.O.M. tubing from 1-10

inches O.D. "Smart-Screen" operator controls allow complete machine changeover

normally in less than five minutes.

The abrasive belt grinding process and the automatic tube handling system help provide a very cost effective and productive integrated system for high volume O.D. tube and rod grinding when compared to other methods, including bonded wheel centerless grinding and CNC turning. This method of centerless abrasive belt grinding has become a universal standard in the hydraulic cylinder industry for both low and high production requirements for tube and rod finishing on many types of truck lift cylinders in the United States, Canada, England and Brazil.

Case 3: Brass Lock Hardware

High production, continuous, in-line buffing and satin finishing systems

with programmable controls for rapid machine changeover offer maximum

flexibility to finish brass doorknobs and rosettes for a variety of different

lock hardware styles. Production rates of 6,000 parts per hour are feasible.

|

Figure 7 illustrates an in-line conveyor machine with seven adjustable buffing heads. They are controlled by a "smart-screen" with menu-driven software (Figure 8) for ease of operator control. The buffing heads are equipped with automatic head positioning through a Programmable Logic Controller (PLC) system. This concept allows the manufacturer to produce at high rates and still have the ability to changeover quickly to other part styles to meet "just-in-time" production scheduling goals.

Case 4: Brass and Aluminum Levers

One of twelve robotic finishing work cells for decorative lock hardware

uses coated abrasive belts and nylon abrasive belts/wheels to satin finish

various door levers in a programmable work cell. The overall systems shown

in Figures

9 - 10 show how an Acme designed over and under and a six-sided part

server are integrated into the systems. These arrangements allow the robotic

cells to run for several hours without need of operator attention. The

indexing part server is designed to allow the addition of a second robot.

This will double output without adding additional material handling.

|

|

|

The robotic cell is completely enclosed in a sheet metal housing to meet safety and environmental requirements. Figure 12 shows the robot satin finishing the underside of a brass lever using a nylon abrasive wheel for consistent and uniform cosmetic finishes.

Case 5: Brass Plumbing Castings

A variety of different

brass cast plumbing housings, bases and faucet spouts are ground and polished

in a robotic work cell, as shown in Figures

13 to 16. The parts are selected from multiple queuing trays. Dual

trays provide a continuous part supply to the robot for approximately

one to two hours, as shown in Figure

13. A series of four coated abrasive belt operations rough grind and

finish polish the contoured shaped brass castings on a consistent and

repeatable basis. Custom software provides the operator with a simplified

menu-controlled screen for changing part programs and maximizing the abrasive

belt life by use of programmable force-control and variable belt speeds

on the grinding/polishing heads.

|

|

|

|

Case 6: Aluminum Extrusions

The buffing of aluminum extrusions can be programmed on a 4-ft wide by

24-ft long stationary worktable in conjunction with a wide traversing

buffing head. A series of extrusions can be preloaded on interchangeable

work platens for more efficient part handling to maximize "up time" on

the buffing table. The basic machine, Figure

17, is enclosed in a sheet metal house to control the environmental

conditions from the operator. The operator can load the fixtured worktable

outside the house enclosure from both sides of the machine (Figure

18). A programmable control system is provided with a CRT screen for

ease of operation control and monitoring. An automatic multiple spray

gun compound system is mounted on a 40 hp, 4-ft wide traversing buffing

head for "cut and color" buffing operations. Satin finishing operations

can also be adapted when using nylon abrasive finishing wheels for added

machine flexibility.

|

Case 7: Stainless Steel Ball Valves

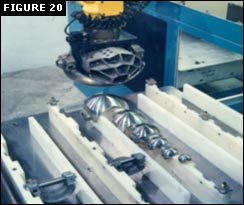

A robotic work cell is

capable of abrasive belt polishing and buffing to a mirror finish a family

of stainless steel ball valves in sizes from 1-12 inches O.D. In Figure

19, the robot is located on a common base with two belt heads and

two buff heads, with exhaust ducts mounted in the base and connected to

an exhaust system for dust collection evaluation. In Figure

20, the family of ball valves are fixtured on queuing trays with dual

drawers for intermittent operator load and unload, without affecting the

robot operation. The robot controls are provided with "operator friendly"

software through a Smart Screen for ease of operator control. The 12-inch

O.D. ball valve, weighing 90-100 lb, is the largest ball valve of many

sizes to be programmed in the robotic work cell. This particular application

demonstrates excellent flexibility of a robotic work cell performing a

number of difficult edge deburring and super finishing operations that

were previously performed in manual operations.

|

It is important to note that many manual operations of this type are being converted to robotic polishing and buffing methods. The manual fatigue factor of handling the larger ball valves is now minimized at greatly reduced cycle times for a very cost effective operation. In addition, new structured abrasive belt products help to provide more efficient belt polishing operations by reducing the number of abrasive belt sequences in order to achieve a final mirror finish throughout the ball valve family of parts.

Case 8: Robotic Grinding, Polishing, and Buffing of Orthopedic

Implants

Another classic benchmark robotic application includes the grinding, polishing,

and buffing of knee implant prostheses parts, which in the past had required

an equivalent of 15-20 manual polishers to perform the work of one robotic

work cell (Figures

20 and 21) Acme robotic work cells have evolved to a level where grinding

and polishing can combine gate removal, contour and tolerance grinding,

and super finishing of chrome-cobalt investment cast knee and hip implants

using very sophisticated finishing technology.

|

In summary, the global market factors will continue to push our manufacturing and finishing concepts to higher levels of achievement. The changes in mechanical finishing for cosmetic and functional part products have been greatly influenced through growing technology of robotic and computer controlled finishing processes and systems. Progressive companies today must support and encourage continuous improvement and concepts in order to grow and maintain a strong position in their particular future markets. As we move into the new millennium, these changes will continue to expand throughout the U.S. and the world economy.

Serving the Finishing Industries. Since 1936.

PF Online and all contents

are properties of Gardner Publications, Inc.

All Rights Reserved.